Chemical Joint Grouting

Elite Pipeline Services (EPS) is a provider of Joint Chemical Grouting Services. This joint grouting allows us to reduce or eliminate the infiltration of manholes and sewer lines, which is accomplished by sealing both the defect and the adjacent soil. Grout can be applied over a large area, at lateral joints, or at specific points along the main line. For chemical grouting to be effective, the surrounding soil should be stable enough to retain the grout.

EPS uses a variety of chemical grouts to seal pipe joints and sewer connections. It is essential to use a grout that is compatible with the pipe, as well as the soil conditions that surround the defect. A two-part epoxy resin grout is used to prevent clogging in the feed pipes. The two resin grouts are fed into the packer via two separate pipes, where it is mixed prior to injection.

When grouting localized defects, an epoxy resin or mortar is used, while a chemical mix is required for the flood grouting of large sections of sewer mains and laterals. In either case, it is essential to clean the host pipe.

Localized chemical joint grouting involves the use of inflatable packers to isolate the soon to be grouted joint from the rest of the sewer system. The inflatable packers are sized to the section of the pipe, which allows the controlled application of grout to only the part of the sewer sealed off by the packer. The packer is first pulled into position over the defected joint or connection area. It is then inflated to seal off the area for grouting. The pipes then feed the grout to the packer, where it is injected into the pipe cavity, defective areas, and soil outside the defective area of the pipe.

EPS uses a variety of chemical grouts to seal pipe joints and sewer connections. It is essential to use a grout that is compatible with the pipe, as well as the soil conditions that surround the defect. A two-part epoxy resin grout is used to prevent clogging in the feed pipes. The two resin grouts are fed into the packer via two separate pipes, where it is mixed prior to injection.

When grouting localized defects, an epoxy resin or mortar is used, while a chemical mix is required for the flood grouting of large sections of sewer mains and laterals. In either case, it is essential to clean the host pipe.

Localized chemical joint grouting involves the use of inflatable packers to isolate the soon to be grouted joint from the rest of the sewer system. The inflatable packers are sized to the section of the pipe, which allows the controlled application of grout to only the part of the sewer sealed off by the packer. The packer is first pulled into position over the defected joint or connection area. It is then inflated to seal off the area for grouting. The pipes then feed the grout to the packer, where it is injected into the pipe cavity, defective areas, and soil outside the defective area of the pipe.

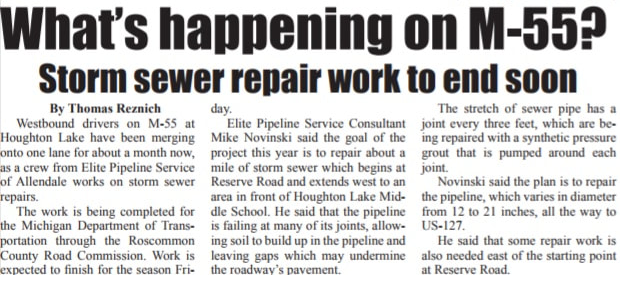

The Houghton Lake Resorter

Article and Photo Cred: Thomas Reznich