SIPP: Spray In Place Pipe

SIPP Rehabilitation from Elite Pipeline & Genesis

The best nuclear pipeline rehabilitation solutions are driven by innovative technology that constantly pushes the boundaries of what is possible in the nuclear piping sector. The state-of-the-art spray in place pipe lining process, also known as SIPP. Designed with efficiency, longevity and cost-effectiveness in mind, SIPP is a pipe coating and repair service which applies a resin lining to improve, repair the condition of the piping.

At Elite Pipeline we have joined with Genesis Pipeline Rehabilitation, together we are one of America’s leading providers of SIPP, championing the technology for our clients to help them keep their nuclear piping systems protected and working at their optimum capacity.

Our SIPP service uses a100% solids, polymeric material. It is sourced from the best supplier on the market and is NSF-61 certified, the best rating for use in potable water systems. Hand-in-hand with our tried and tested cleaning process, SIPP will keep piping cleaner, safer and more reliable, maintaining its integrity in the short term and throughout a Subsequent License Renewal period of extended operation.

A SIPP lining can be applied as a corrosion barrier or thick enough to be a structural replacement for the host pipe. Since SIPP is non-metallic, a SIPP structural replacement eliminates the need for cathodic protection.

Thanks to our tools and technology, SIPP is a no-dig rehabilitation solution. This means the disruption of your plant site and operations is minimal, while our results speak effectively for themselves.

At Elite Pipeline we have joined with Genesis Pipeline Rehabilitation, together we are one of America’s leading providers of SIPP, championing the technology for our clients to help them keep their nuclear piping systems protected and working at their optimum capacity.

Our SIPP service uses a100% solids, polymeric material. It is sourced from the best supplier on the market and is NSF-61 certified, the best rating for use in potable water systems. Hand-in-hand with our tried and tested cleaning process, SIPP will keep piping cleaner, safer and more reliable, maintaining its integrity in the short term and throughout a Subsequent License Renewal period of extended operation.

A SIPP lining can be applied as a corrosion barrier or thick enough to be a structural replacement for the host pipe. Since SIPP is non-metallic, a SIPP structural replacement eliminates the need for cathodic protection.

Thanks to our tools and technology, SIPP is a no-dig rehabilitation solution. This means the disruption of your plant site and operations is minimal, while our results speak effectively for themselves.

Philip H. Kohn, P.E., MBA

Principal Engineer

Phil is a Registered Professional Engineer with an MBA and 42 years of technical, supervisory, program and project management experience in the nuclear industry at commercial, U. S. Department of Energy (DOE), and military facilities. Phil has used his diverse experience and education together with his attention to detail to implement innovative improvements in many nuclear programs and projects. These resulted in substantial cost and schedule savings while maintaining or improving quality and safety.

2024 - 24" Coating Project

|

SIPP in 24"

|

SIPP Climbing Vertical in 24"

|

SIPP In NUCLEAR

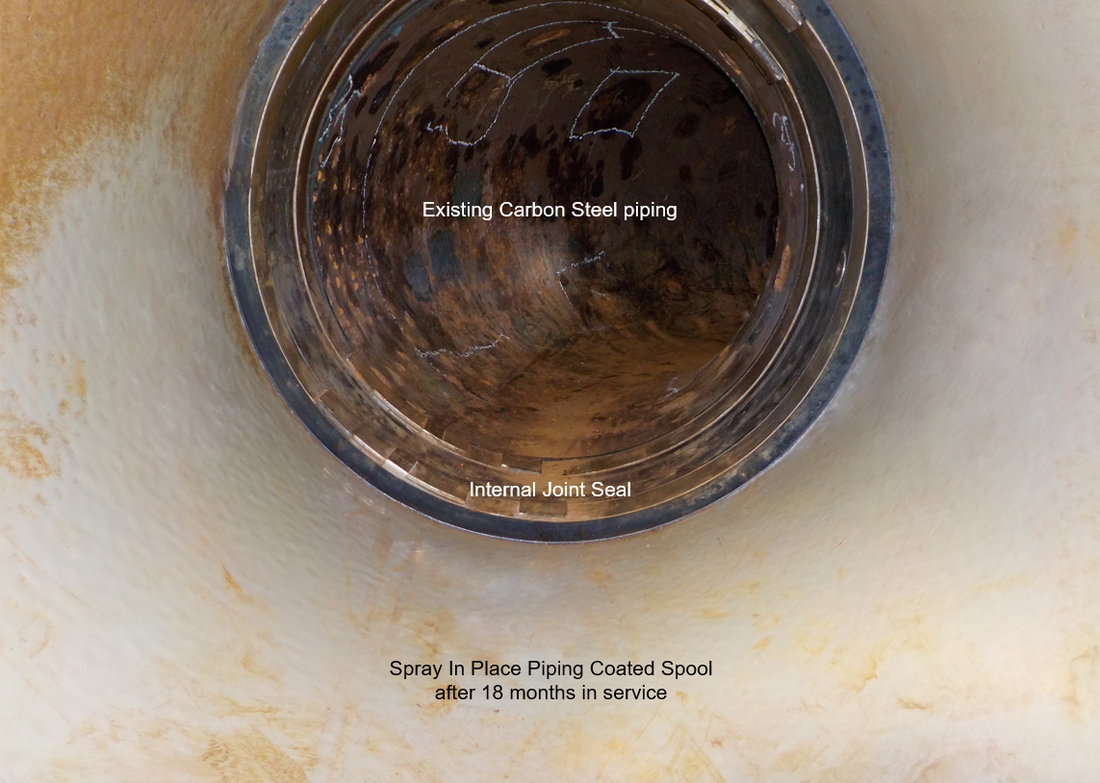

Elite Pipeline Services along with Genesis continues to accelerate nuclear pipeline repairs using Spray In Place Pipe (SIPP) trenchless robotic application.

Piping can be hydro-lazed up to 35,000 psi for contaminant removal and surface prep.

Steel piping then coated with approximate 160-200 mils of IC-202 using our robotic application.

Piping can be hydro-lazed up to 35,000 psi for contaminant removal and surface prep.

Steel piping then coated with approximate 160-200 mils of IC-202 using our robotic application.

All Testing in Compliant of ASTM D4541 Standard Test Method for Pull-Off Strength of Coatings

Benefit of this technology

|

|

Inspection - Cleaning -Lining

Our hard-working Elite specialists are industry experts, with decades of experience in nuclear piping rehabilitation. To ensure we consistently provide the best service we can for our sector, we always stay ahead of the game, positioning ourselves as pioneers through careful research and industry knowledge. We are trusted by 30+ nuclear plants for our pipeline rehabilitation and assessments, we bring dedication, safety and quality, bringing a host of services, including SIPP, at a cost-friendly pricing structure.